Infection control: new copper surface kills bacteria 100 times faster

Researchers from CSIRO and RMIT University have developed a new copper surface that is said to kill the bacteria over 100 times faster than standard copper and could help combat antibiotic-resistant superbugs.

University’s Distinguished Professor Ma Qian said a standard copper surface will kill about 97% of golden staph within four hours. When the researchers placed golden staph bacteria on the specially designed copper surface, it destroyed more than 99.99% of the cells in just two minutes, according to Qian.

Not only is it more effective, it’s 120 times faster, Qian said, noting that the results were achieved without the assistance of any drug. “Our copper structure has shown itself to be remarkably potent for such a common material,” he said.

The team believes there could be a huge range of applications for the new material once further developed, including antimicrobial doorhandles and other touch surfaces in schools, hospitals, homes and public transport, as well as filters in antimicrobial respirators or air ventilation systems, and in face masks.

The researchers are now looking to investigate the enhanced copper’s effectiveness against SARS-COV-2, the virus that causes COVID-19, including assessing 3D-printed samples. Other studies suggest copper may be highly effective against the virus, leading the US Environmental Protection Agency to officially approve copper surfaces for antiviral uses earlier this year.

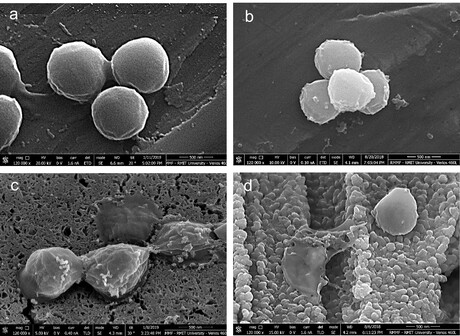

Study lead author Dr Jackson Leigh Smith said the copper’s unique porous structure was key to its effectiveness as a rapid bacteria killer. A special copper mould casting process was used to make the alloy, arranging copper and manganese atoms into specific formations.

The manganese atoms were then removed from the alloy using a cheap and scalable chemical process called ‘dealloying’, leaving pure copper full of tiny microscale and nanoscale cavities in its surface.

“Our copper is composed of comb-like microscale cavities and within each tooth of that comb structure are much smaller nanoscale cavities; it has a massive active surface area,” Smith said.

“The pattern also makes the surface super hydrophilic, or water-loving, so that water lies on it as a flat film rather than as droplets.

“The hydrophilic effect means bacterial cells struggle to hold their form as they are stretched by the surface nanostructure, while the porous pattern allows copper ions to release faster.

“These combined effects not only cause structural degradation of bacterial cells, making them more vulnerable to the poisonous copper ions, but also facilitates uptake of copper ions into the bacterial cells,” Smith said.

“It’s that combination of effects that results in greatly accelerated elimination of bacteria.”

Dr Daniel Liang of CSIRO said researchers across the world were looking to develop new medical materials and devices that could help reduce the rise of antibiotic-resistant superbugs by reducing the need for antibiotics.

“Drug-resistant infections are on the rise, and with limited new antibiotics coming onto the market, the development of materials resistant to bacteria will likely play an important role in helping address the problem,” Liang said.

“This new copper product offers a promising and affordable option to fighting superbugs, and is just one example of CSIRO’s work in helping to address the growing risk of antibiotic resistance.”

This study was initiated through an RMIT-CSIRO PhD program and was subsequently co-funded by the CASS Foundation in Melbourne, Australia. The innovative process now has patents pending in the USA, China and Australia.

Copper has long been used to fight different strains of bacteria, including the commonly found golden staph, because the ions released from the metal’s surface are toxic to bacterial cells.

$1bn vaccine and antivenom manufacturing facility opens

A $1 billion cell-based influenza vaccine and antivenom manufacturing facility has opened in...

National concussion clinical guidelines now available

The first Australia- and New Zealand-specific guidelines for all forms of concussion — from...

Doctors criticise "risky prescribing agenda"

The AMA and RACGP have expressed disappointment in the Pharmacy Board of Australia's...

![[New Zealand] Transform from Security Awareness to a Security Culture: A Vital Shift for SMB Healthcare — Webinar](https://d1v1e13ebw3o15.cloudfront.net/data/89856/wfmedia_thumb/..jpg)

![[Australia] Transform from Security Awareness to a Security Culture: A Vital Shift for SMB Healthcare — Webinar](https://d1v1e13ebw3o15.cloudfront.net/data/89855/wfmedia_thumb/..jpg)